正在热播

电影

更多电影

1981

喜剧片

中国香港

HD

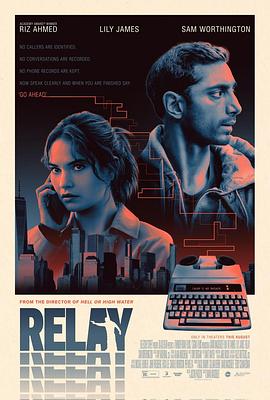

2024

恐怖片

美国

里兹·阿迈德 莉莉·詹姆斯 薇拉·菲茨杰拉德 萨姆·沃辛顿 马修·马希尔 Aaron Roman Weiner Helen Eigenberg 伊萨·戴维斯 普鲁瓦·贝迪 格兰特·哈里森 PJ Adzima Brian O'Neill 普·班德赫 何塞·冈斯·阿尔维斯 John Cashin Jessica Marza 霍尔登·古德曼 杰夫·比尔 Jamie Ann Burke Kerri Louise

《传话人》讲述了一位名叫林默的普通快递员,意外卷入一场错综复杂的都市迷局。他因工作之便成为各方势力传递秘密信息的中间桥梁,却在不经意间获悉了一桩涉及政商勾结的重大阴谋。原本只求安稳度日的他,被迫在良知

HD

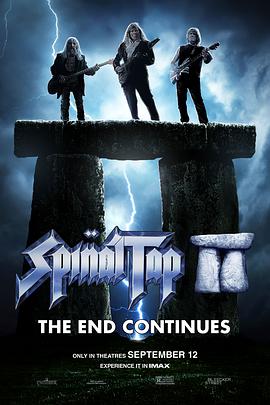

2025

喜剧片

美国

《摇滚万万岁2》延续了前作的荒诞与热血,讲述过气乐队“脊柱穿刺”再度聚首的爆笑之旅。时过境迁,成员们已散落天涯:主唱转行卖香肠,鼓手出家修行,吉他手沦为商场促销员。然而一场突如其来的音乐节邀请,让这群

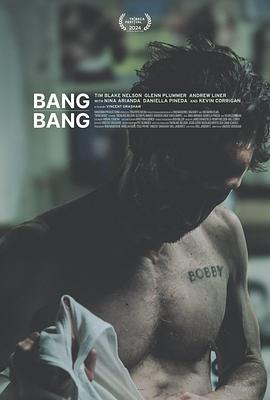

HDTS

2024

剧情片

美国

《拳影人生》讲述了一位中年落魄的拳击手李振东在人生最低谷时,意外接手经营一家濒临倒闭的拳馆,并与一群背景各异、心怀梦想的年轻学员相互砥砺的故事。片中,李振东不仅要在擂台上直面昔日对手的挑战,还要在生活

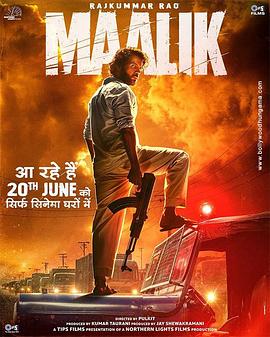

HDTS

2025

动作片

印度

在《马利克》这部充满张力与深度的影片中,主角马利克是一位身陷家族恩怨与自我救赎漩涡的复杂人物。故事以一场突如其来的家族悲剧为引,揭开埋藏多年的权力争夺与情感纠葛。马利克被迫在忠诚与背叛之间做出抉择,同

HD

2025

恐怖片

西班牙

凯特·德尔·卡斯蒂洛 布鲁诺·比齐尔 Daniela Schmidt 伊万·马科斯 Garrett Wall Alex Diehl 肯·阿普多恩 Jhony Giraldo Megan Tyler Moreno 埃玛·苏亚雷斯

在《本能2025》中,一场科技与人性的致命博弈悄然展开。未来世界,人类欲望可通过神经植入系统被量化操控,犯罪心理学家林雪与系统设计师陈锐被迫联手追查一系列离奇命案。两人发现所有线索都指向一款名为“本能

HD

2024

剧情片

土耳其

Bülent Emin Yarar Hülya Gülsen Irmak Cem Zeynel Kili? ?zgür Emre Yildirim Duygu G?khan Durukan ?elikkaya

《哈基》讲述了一位名叫哈基的流浪少年在都市边缘挣扎求生的动人故事。衣衫褴褛却眼神倔强的哈基,每日依靠捡拾废品与打零工勉强维生,直到他在废弃车站偶遇了神秘独居老人老金。两人从最初的戒备试探,逐渐发展出跨

HD

2024

犯罪片

西班牙

米格尔·埃尔南 苏珊娜·阿巴图纳·戈麦斯 亚历山德拉·玛桑凯 Stanzin Gonbo Sonam Angchok 伊万·雷内多 Morup Namgyal Kunga Dodon Tsewang Lazes Stanzin Sharap Leo Medina Carla León 帕维尔·安东 Jerome Cabodoc Eloisa Luján Yasoda Goteea Mahesh Harjani

在神秘莫测的《暗影谷》,一位失去记忆的年轻探险家艾琳意外闯入这片被远古诅咒笼罩的禁地。她与隐居山谷的老猎人卡尔结成盟友,两人在迷雾笼罩的森林中寻找真相,却逐渐发现山谷的异变与艾琳消失的过去有着惊人关联

HD

2025

恐怖片

韩国

TC

2008

剧情片

中国香港

HD

2001

恐怖片

中国香港

HD

2025

喜剧片

中国大陆,中国香港

TC抢先版

2025

喜剧片

中国大陆,中国香港

TC

2024

恐怖片

墨西哥

在神秘病毒席卷都市的危机背景下,《魔种入体》讲述了平凡程序员张默意外被植入远古魔种,身体逐渐异变并觉醒超能力的故事。他不仅要面对政府特工的追捕和神秘组织的利用,更需在人性与魔性的拉扯中守护家人与挚爱。

HD

1992

剧情片

中国香港

HD

连续剧

更多连续剧

2025

国产剧

中国大陆

更新至02集

2025

国产剧

中国香港

更新至03集

2025

国产剧

中国香港

更新至03集

更新至20集

2025

韩国剧

韩国

更新至50集

2025

日本剧

日本

更新至01集

2025

日本剧

日本

更新至66集

2025

日本剧

日本

更新至01集

2025

国产剧

中国大陆

更新至06集

2025

日本剧

日本

更新至02集

2023

日本剧

日本

更新至03集

2025

美国剧

美国

《海军罪案调查处:欧洲喋血篇》聚焦NCIS精英小队远赴欧洲破解一桩跨国要案。当一名海军军官在维也纳歌剧院离奇死亡,吉布斯带领团队与当地警方合作,却卷入牵扯多国势力的暗杀阴谋。剧情穿梭于历史悠久的欧洲地

更新至02集

2017

香港剧

中国香港

更新至2588集

2025

日本剧

日本

更新至01集

2025

韩国剧

韩国

更新至01集

综艺

更多综艺

1997

港台综艺

中国台湾

更新至20250704期

2020

港台综艺

中国台湾

更新至20250701期

2020

港台综艺

中国台湾

更新至20250630期

2006

港台综艺

中国台湾

更新至20250630期

2011

港台综艺

中国台湾

更新至20250630期

2016

港台综艺

中国台湾

更新至20250630期

2025

日韩综艺

韩国

《偶像庆典大作战:全国快闪巡演》讲述了人气偶像团体“Starlight”为挽救濒临解散的危机,毅然发起一场跨越十座城市的快闪巡演挑战。性格迥异的五位成员必须在有限的资金与时间内,秘密策划并执行每一场即

更新至03集

2025

大陆综艺

中国大陆

更新至20250702期

2025

大陆综艺

中国大陆

更新至20250701期

2011

大陆综艺

中国大陆

更新至20250704期

2011

大陆综艺

中国大陆

更新至20250704期

2010

大陆综艺

中国大陆

更新至20250701期

2018

大陆综艺

大陆

更新至20250701期

动漫

更多动漫

2025

日韩动漫

日本

更新至01集

2025

日韩动漫

日本

更新至02集

2025

日韩动漫

日本

更新至01集

2025

国产动漫

中国大陆

《这个年纪还能当大侠吗第二季》延续了第一季的热血与幽默,讲述年近中年的镖师张大川在江湖再起风云之际,毅然选择重出江湖,与一群性格迥异的“老伙计”共同对抗新兴邪派势力的故事。本季中,张大川不仅要面对家庭

更新至03集

2025

日韩动漫

日本

更新至02集

2025

日韩动漫

日本

更新至01集

2023

国产动漫

中国大陆

更新至138集

2025

国产动漫

中国大陆

更新至08集

2024

国产动漫

中国大陆

更新至83集

2025

国产动漫

大陆

在异世界迎来毁灭的时刻,主人公陈木带着无数神秘货币重生,醒来后发现自己已经变身为一名神秘投资者。而其他人为了一点微不足道的金钱而争斗时,陈木却开始了大手笔的投资行动,纷纷收购各种神秘场景。他不再被局限

更新至53集

2025

国产动漫

中国大陆

更新至05集

2025

日韩动漫

日本

更新至01集

2021

国产动漫

内地

更新至166集

2025

日韩动漫

日本

更新至01集

2025

日韩动漫

日本

更新至01集

短剧

更多短剧

2025

女频恋爱

中国大陆

全集

2025

现代都市

中国大陆

全集

2025

现代都市

中国大陆

全集

2025

女频恋爱

中国大陆

全集

2025

现代都市

中国大陆

全集

2025

女频恋爱

中国大陆

在《假扮情侣我竟是他的朱砂痣》中,职场新人林薇为摆脱纠缠,无奈与高冷总裁顾泽签订“假扮情侣协议”,本以为只是一场各取所需的交易,却在朝夕相处的演技较量中逐渐心动。然而她意外发现,自己竟与顾泽记忆中难以

全集

2025

现代都市

中国大陆

全集

2025

古装仙侠

中国大陆

全集

2025

反转爽剧

中国大陆

在宁静的乡村生活中,七岁的小宝天真烂漫,却不知自己身负惊天秘密——他竟是南朝流落民间的太子爷!随着神秘势力的追踪与皇室旧部的突然到访,小宝的平凡日常被彻底打破。养父为保护他拼死抵抗,而南朝权谋漩涡中的

全集

2025

现代都市

中国大陆

全集

2025

女频恋爱

中国大陆

全集

2025

现代都市

中国大陆

全集

2025

古装仙侠

中国大陆

《我手执封神榜身背打神鞭下山》讲述了一位身负天命的神秘修士,手持掌控天地秩序的封神榜,身背可诛仙灭魔的打神鞭,毅然踏入凡尘乱世的传奇旅程。他本是昆仑山上的隐修弟子,为平息人间妖魔肆虐、朝纲崩乱的危局,

全集

2025

女频恋爱

中国大陆

全集

2025

年代穿越

中国大陆

全集

最新影片

选择类型

全部

电影

连续剧

综艺

动漫

短剧

2025

女频恋爱

中国大陆

全集

2025

现代都市

中国大陆

全集

1981

喜剧片

中国香港

HD

2025

国产剧

中国大陆

更新至02集

2024

恐怖片

美国

里兹·阿迈德 莉莉·詹姆斯 薇拉·菲茨杰拉德 萨姆·沃辛顿 马修·马希尔 Aaron Roman Weiner Helen Eigenberg 伊萨·戴维斯 普鲁瓦·贝迪 格兰特·哈里森 PJ Adzima Brian O'Neill 普·班德赫 何塞·冈斯·阿尔维斯 John Cashin Jessica Marza 霍尔登·古德曼 杰夫·比尔 Jamie Ann Burke Kerri Louise

《传话人》讲述了一位名叫林默的普通快递员,意外卷入一场错综复杂的都市迷局。他因工作之便成为各方势力传递秘密信息的中间桥梁,却在不经意间获悉了一桩涉及政商勾结的重大阴谋。原本只求安稳度日的他,被迫在良知

HD

2025

国产剧

中国香港

更新至03集

2025

国产剧

中国香港

更新至03集

2025

日韩动漫

日本

更新至01集

2025

日韩动漫

日本

更新至02集

1997

港台综艺

中国台湾

更新至20250704期

2020

港台综艺

中国台湾

更新至20250701期

2020

港台综艺

中国台湾

更新至20250630期

2006

港台综艺

中国台湾

更新至20250630期

2011

港台综艺

中国台湾

更新至20250630期

1981

喜剧片

中国香港

HD

2024

恐怖片

美国

里兹·阿迈德 莉莉·詹姆斯 薇拉·菲茨杰拉德 萨姆·沃辛顿 马修·马希尔 Aaron Roman Weiner Helen Eigenberg 伊萨·戴维斯 普鲁瓦·贝迪 格兰特·哈里森 PJ Adzima Brian O'Neill 普·班德赫 何塞·冈斯·阿尔维斯 John Cashin Jessica Marza 霍尔登·古德曼 杰夫·比尔 Jamie Ann Burke Kerri Louise

《传话人》讲述了一位名叫林默的普通快递员,意外卷入一场错综复杂的都市迷局。他因工作之便成为各方势力传递秘密信息的中间桥梁,却在不经意间获悉了一桩涉及政商勾结的重大阴谋。原本只求安稳度日的他,被迫在良知

HD

2025

喜剧片

美国

《摇滚万万岁2》延续了前作的荒诞与热血,讲述过气乐队“脊柱穿刺”再度聚首的爆笑之旅。时过境迁,成员们已散落天涯:主唱转行卖香肠,鼓手出家修行,吉他手沦为商场促销员。然而一场突如其来的音乐节邀请,让这群

HDTS

2024

剧情片

美国

《拳影人生》讲述了一位中年落魄的拳击手李振东在人生最低谷时,意外接手经营一家濒临倒闭的拳馆,并与一群背景各异、心怀梦想的年轻学员相互砥砺的故事。片中,李振东不仅要在擂台上直面昔日对手的挑战,还要在生活

HDTS

2025

动作片

印度

在《马利克》这部充满张力与深度的影片中,主角马利克是一位身陷家族恩怨与自我救赎漩涡的复杂人物。故事以一场突如其来的家族悲剧为引,揭开埋藏多年的权力争夺与情感纠葛。马利克被迫在忠诚与背叛之间做出抉择,同

HD

2025

恐怖片

西班牙

凯特·德尔·卡斯蒂洛 布鲁诺·比齐尔 Daniela Schmidt 伊万·马科斯 Garrett Wall Alex Diehl 肯·阿普多恩 Jhony Giraldo Megan Tyler Moreno 埃玛·苏亚雷斯

在《本能2025》中,一场科技与人性的致命博弈悄然展开。未来世界,人类欲望可通过神经植入系统被量化操控,犯罪心理学家林雪与系统设计师陈锐被迫联手追查一系列离奇命案。两人发现所有线索都指向一款名为“本能

HD

2024

剧情片

土耳其

Bülent Emin Yarar Hülya Gülsen Irmak Cem Zeynel Kili? ?zgür Emre Yildirim Duygu G?khan Durukan ?elikkaya

《哈基》讲述了一位名叫哈基的流浪少年在都市边缘挣扎求生的动人故事。衣衫褴褛却眼神倔强的哈基,每日依靠捡拾废品与打零工勉强维生,直到他在废弃车站偶遇了神秘独居老人老金。两人从最初的戒备试探,逐渐发展出跨

HD

2024

犯罪片

西班牙

米格尔·埃尔南 苏珊娜·阿巴图纳·戈麦斯 亚历山德拉·玛桑凯 Stanzin Gonbo Sonam Angchok 伊万·雷内多 Morup Namgyal Kunga Dodon Tsewang Lazes Stanzin Sharap Leo Medina Carla León 帕维尔·安东 Jerome Cabodoc Eloisa Luján Yasoda Goteea Mahesh Harjani

在神秘莫测的《暗影谷》,一位失去记忆的年轻探险家艾琳意外闯入这片被远古诅咒笼罩的禁地。她与隐居山谷的老猎人卡尔结成盟友,两人在迷雾笼罩的森林中寻找真相,却逐渐发现山谷的异变与艾琳消失的过去有着惊人关联

HD

2025

恐怖片

韩国

TC

2008

剧情片

中国香港

HD

2001

恐怖片

中国香港

HD

2025

喜剧片

中国大陆,中国香港

TC抢先版

2025

喜剧片

中国大陆,中国香港

TC

2024

恐怖片

墨西哥

在神秘病毒席卷都市的危机背景下,《魔种入体》讲述了平凡程序员张默意外被植入远古魔种,身体逐渐异变并觉醒超能力的故事。他不仅要面对政府特工的追捕和神秘组织的利用,更需在人性与魔性的拉扯中守护家人与挚爱。

HD

1992

剧情片

中国香港

HD

2025

国产剧

中国大陆

更新至02集

2025

国产剧

中国香港

更新至03集

2025

国产剧

中国香港

更新至03集

更新至20集

2025

韩国剧

韩国

更新至50集

2025

日本剧

日本

更新至01集

2025

日本剧

日本

更新至66集

2025

日本剧

日本

更新至01集

2025

国产剧

中国大陆

更新至06集

2025

日本剧

日本

更新至02集

2023

日本剧

日本

更新至03集

2025

美国剧

美国

《海军罪案调查处:欧洲喋血篇》聚焦NCIS精英小队远赴欧洲破解一桩跨国要案。当一名海军军官在维也纳歌剧院离奇死亡,吉布斯带领团队与当地警方合作,却卷入牵扯多国势力的暗杀阴谋。剧情穿梭于历史悠久的欧洲地

更新至02集

2017

香港剧

中国香港

更新至2588集

2025

日本剧

日本

更新至01集

2025

韩国剧

韩国

更新至01集

1997

港台综艺

中国台湾

更新至20250704期

2020

港台综艺

中国台湾

更新至20250701期

2020

港台综艺

中国台湾

更新至20250630期

2006

港台综艺

中国台湾

更新至20250630期

2011

港台综艺

中国台湾

更新至20250630期

2016

港台综艺

中国台湾

更新至20250630期

2025

日韩综艺

韩国

《偶像庆典大作战:全国快闪巡演》讲述了人气偶像团体“Starlight”为挽救濒临解散的危机,毅然发起一场跨越十座城市的快闪巡演挑战。性格迥异的五位成员必须在有限的资金与时间内,秘密策划并执行每一场即

更新至03集

2025

大陆综艺

中国大陆

更新至20250702期

2025

大陆综艺

中国大陆

更新至20250701期

2011

大陆综艺

中国大陆

更新至20250704期

2011

大陆综艺

中国大陆

更新至20250704期

2010

大陆综艺

中国大陆

更新至20250701期

2018

大陆综艺

大陆

更新至20250701期

2025

日韩动漫

日本

更新至01集

2025

日韩动漫

日本

更新至02集

2025

日韩动漫

日本

更新至01集

2025

国产动漫

中国大陆

《这个年纪还能当大侠吗第二季》延续了第一季的热血与幽默,讲述年近中年的镖师张大川在江湖再起风云之际,毅然选择重出江湖,与一群性格迥异的“老伙计”共同对抗新兴邪派势力的故事。本季中,张大川不仅要面对家庭

更新至03集

2025

日韩动漫

日本

更新至02集

2025

日韩动漫

日本

更新至01集

2023

国产动漫

中国大陆

更新至138集

2025

国产动漫

中国大陆

更新至08集

2024

国产动漫

中国大陆

更新至83集

2025

国产动漫

大陆

在异世界迎来毁灭的时刻,主人公陈木带着无数神秘货币重生,醒来后发现自己已经变身为一名神秘投资者。而其他人为了一点微不足道的金钱而争斗时,陈木却开始了大手笔的投资行动,纷纷收购各种神秘场景。他不再被局限

更新至53集

2025

国产动漫

中国大陆

更新至05集

2025

日韩动漫

日本

更新至01集

2021

国产动漫

内地

更新至166集

2025

日韩动漫

日本

更新至01集

2025

日韩动漫

日本

更新至01集

2025

女频恋爱

中国大陆

全集

2025

现代都市

中国大陆

全集

2025

现代都市

中国大陆

全集

2025

女频恋爱

中国大陆

全集

2025

现代都市

中国大陆

全集

2025

女频恋爱

中国大陆

在《假扮情侣我竟是他的朱砂痣》中,职场新人林薇为摆脱纠缠,无奈与高冷总裁顾泽签订“假扮情侣协议”,本以为只是一场各取所需的交易,却在朝夕相处的演技较量中逐渐心动。然而她意外发现,自己竟与顾泽记忆中难以

全集

2025

现代都市

中国大陆

全集

2025

古装仙侠

中国大陆

全集

2025

反转爽剧

中国大陆

在宁静的乡村生活中,七岁的小宝天真烂漫,却不知自己身负惊天秘密——他竟是南朝流落民间的太子爷!随着神秘势力的追踪与皇室旧部的突然到访,小宝的平凡日常被彻底打破。养父为保护他拼死抵抗,而南朝权谋漩涡中的

全集

2025

现代都市

中国大陆

全集

2025

女频恋爱

中国大陆

全集

2025

现代都市

中国大陆

全集

2025

古装仙侠

中国大陆

《我手执封神榜身背打神鞭下山》讲述了一位身负天命的神秘修士,手持掌控天地秩序的封神榜,身背可诛仙灭魔的打神鞭,毅然踏入凡尘乱世的传奇旅程。他本是昆仑山上的隐修弟子,为平息人间妖魔肆虐、朝纲崩乱的危局,

全集

2025

女频恋爱

中国大陆

全集

2025

年代穿越

中国大陆

全集